ONLINE EXCLUSIVE:

Driving Lean Manufacturing Implementation: Starting with Cultural Transformation

By Kenneth J. Rufino Nina

Companies implement various production strategies to improve efficiency, cost effectiveness and competitiveness through system optimization. Lean manufacturing leads the pack as a proven strategy to address these key factors. Still, many industries around the world fail in the implementation of programs to achieve the optimum level of lean. Why? Industries often make mistakes about what constitutes the essentials of lean manufacturing.

Successful execution of lean concepts requires thorough understanding across the entire organization of lean principles, behaviors and systems. Lean involves more than cutting costs, reviewing metrics, mapping processes and developing major changes. And lean is not just about benchmarking Japanese products where, for example, Toyota Systems are simply copied and pasted. Instead, lean is about creating a culture.

Culture is defined as a set of common behaviors attributed to a group of individuals with similar backgrounds, stories and habits. Companies must take this definition to heart in creating a culture where those backgrounds, stories and habits come together to form a workforce that supports lean manufacturing. Companies that develop strong bonds with their employees at all levels will achieve success in creating an appropriate people culture. The people culture will ultimately lead to effective workforce changes and new systems implementation, both of which drive results for their companies.

Cultural transformation is essentially a journey. In this transformative process, companies will encounter employees resistant to change. To remedy, or even circumvent these behaviors, the company must obtain manager/operator engagement in the process and institute an effective training process. Disciplinary action is not out of the question for those recalcitrant employees stuck in the old mindset. These are not easy steps, yet they are necessary ones to ensure proper synchronization of the management team in working with their employees to develop and maintain lean systems. Employees are the key players because they know and work the systems that drive the company and understand the historical issues and challenges that come with the successful function of a company.

Value-added tools are available to help companies with implementing lean processes. For example, the Gemba walk is a lean basics concept that involves frequent meetings of the multifunctional management team on the shop operations floor. The team discusses metrics, priorities and anything related to shop operations effectiveness. It’s an opportunity for the management team to live lean, be lean, create culture, listen to operators and respond with a sense of urgency to operators’ concerns. It goes beyond the management team just visiting the floor, yet failing to explain the metrics to employees.

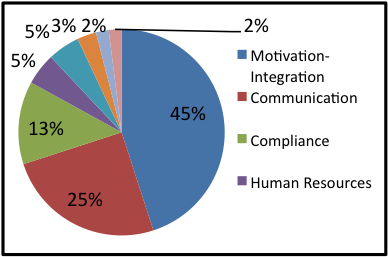

A recent survey at a medical devices company demonstrated that lack of integration, motivation and communication are the main reasons why lean fails and people do not think lean.

|

|

| Figure 2. Lean manufacturing success factors |

Surveys and shop operations experience in medical devices and electronic manufacturing industries present constant reminders about the key factors that result in the success of lean programs. Leaders forget that peoples’ perceptions drive change. To achieve proper cultural transformation, consistency of essentials factors is required: integration, a capable workforce, workforce development, communication and motivation. Workforce alignment and satisfaction improve the work environment and increase a sense of competitiveness. The success of lean manufacturing requires a step-by-step process that begins with the first step certain to add value — the people.

As Helen Keller so aptly put it, “Alone we can do so little, together we can do so much.”

Juran, Joseph M. (2008). Juran’s quality handbook. California, USA. 5th ed.p. cm. ISBN 0-07-034003

Adrienne, Selko (2012). Employees First, Customers Second. Reversed leadership style produces results. Retrieved from http://industryweek.com/articles/employees_first_customers_second_26607.aspx?SectionID=6. Access April 18, 2012.

Taylor, Bill Ray (Feb 28) 2012. Live Webinar: Mindsets & Behaviors with Billy Ray Taylor - Plant Manager, Goodyear Retrieved from http://r20.rs6.net/tn.jsp?et=1109378830453&s=12538&e=001DcsssTkPnSHEPe7_iQMIGWq9mD9qZS0irFEohf-al0y-kjWjbpei1zsnlU7TdjEimPwKWCFC__-x_705wbzpvqs-FKqIEU3pUjlpxURyDsNQzPYbrlPNTg== Access April 17,2012.

http://industryweek.com/articles/employees_first_customers_second_26607.aspx?SectionID=6. Employees First Customer Second. Access April 18,2012

Kenneth Rufino Nina holds a bachelor’s degree in industrial engineering from the University of Puerto Rico and is currently pursuing a master’s degree in manufacturing engineering/quality management focused on key quality foundations. Rufino worked for General Electric as lean/manufacturing engineer, manufacturing supervisor, facilities engineer, energy consumption projects manager and most recently as productivity (or VIP) leader. He currently works as a business excellence site leader at Vention Medical, Inc. in Puerto Rico. At Vention, Nina is in charge of lean program implementation, development of people engagement initiatives, energy savings activities and cost savings projects.