|

|

Mark Doman |

One of the most valuable lessons I have learned while leading lean workouts and teaching the Lean Kaizen course at Oakland University is how important it is for a team to first grasp the current condition. Why? Because unless the team honestly and thoroughly determines the current condition, there is little hope of solving the root causes of the problems and developing effective solutions.

Every member of the team needs to “see and feel” what is actually going on before the team can do anything else.

Like any other intensive investigation, this means going to the gemba (many times), getting on-the-ground facts and mapping the real current condition of the process in question.

In my experience, most teams just don’t have the patience and discipline to do it right. They feel they are too busy or already know all the answers to spend the time to understand and document the process as it actually operates. They take shortcuts. They look at reports, talk to one or two so-called experts or just map how they think the process should operate.

They want to do before they know. They don’t realize that grasping the current condition takes time and highly developed observation skills. Think The Mentalist, with Patrick Jayne (Simon Baker), and his uncanny powers of observation or, for those of you in my generation, picture Lt. Columbo (Peter Falk) plodding through his investigation.

That’s why I like to use the PDCA icon with the over-weighted “Plan” piece of the pie chart:

|

This icon illustrates the correct emphasis — planning — as the first and most important part of the Lean Workout exercise. Planning starts with thoroughly grasping the current condition.

The very first assignment I give to Kaizen teams — after they meet with the team sponsors and hear about the problem and the background — go to the gemba!

And when you go to the gemba, don’t just stroll around the factory floor. Stop and really look at the people and processes. Record your observations and gather facts. Write down what you know and what you don’t know. Ask questions of the people doing the work to better understand what is happening and why it is happening.

Stay put and really watch all the steps in the process. Think about Taiichi Ohno’s practice of drawing a chalk circle on the factory floor and standing there for hours studying what was happening around him so he could see the waste and discern potential root causes.

When the teams finish their first visit to the gemba, they do a 10-minute readout to the whole group that addresses these four basic areas:

1. Report what the members of your team experienced during the visit:

- What did you see? (Take pictures)

- What did you hear? (Ask questions)

- What did you feel? (Take notes)

|

|

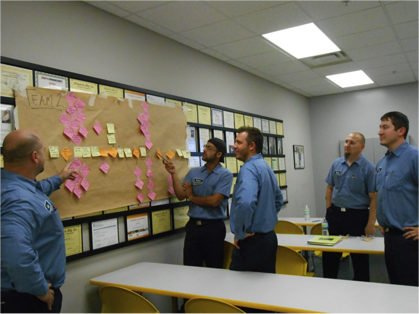

A facility team works through the brown paper exercise. |

2. Describe the basic value stream map of the business --> Process map:

- What does the business/organization do?

- How does the business/organization make its product(s) or perform its service(s)? (Start to draft the process map)

- Who are the key stakeholders?

- Who are the suppliers? (What do they supply?)

- Who are the customers? (What are their requirements?)

- What are the obstacles preventing reaching the ideal state?

3. Identify the waste/muda your team saw:

- Motion

- Waiting

- Conveyance

- Correction

- Overprocessing

- Inventory

- Overproduction

- Knowledge Disconnection

4. Relate first reactions, thoughts and insights

After the team makes its initial visit to the gemba, I have the team members start right in with one of my “go-to” lean tools — the brown paper exercise. The only materials they need are a big roll of brown wrapping paper, tape, scissors, colored sticky notes, magic markers and a long wall in a conference room or work area.

After a short instruction to the team about how to use the various colored sticky notes to identify the specific steps in a process and how to draw the product and information flow lines on the paper, I cut a 10-foot piece of the brown paper and tape it on the wall, and away the team goes.

The brown paper exercise is the best tool I know to get everybody on his or her feet and focused right away on the task at hand.

It jump-starts the lean workout with an activity in which every member of the team can participate and have a voice. The brown paper exercise, if done right, focuses everyone’s attention on the task at hand — understanding how the current process actually works.

I encourage all the team members to grab the sticky notes and write what they saw and learned at the gemba, not what they think is the right answer. If they don’t know, go back to the gemba. I encourage them to challenge each other about the steps in the process, pose questions if they are not sure, go back to the gemba and continually revise their process map until all the team members understand and agree on the current condition.

The brown paper exercise is a multifaceted lean tool that helps do many critical things at the beginning of the lean workout process. The brown paper exercise among other things:

- Engages all the team members and accelerates the team-building process

- Shows early on what the team does not know about the process

- Exposes so-called facts and myths about the process

- Highlights the key problem areas

- Makes public what the team believes are the value-added and wasteful steps of a process

- Amazes everybody about how many steps there are in the process … and how much is waste

|

When most teams think they are done with the brown paper exercise and start to move to the root cause analysis stage, they generally find out pretty quickly that they have to retrace their steps and get more information about the current condition to proceed. They need to go back to the gemba to answer the questions that inevitably arise either from the team or from me.

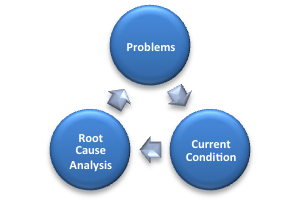

The most successful teams keep looping back to better understand the problems-->current condition-->root cause analysis. As the figure on the left indicates:

The more they work on their analysis, the more information they need and the better they understand their problems and the root causes.

I don’t let them off the hook. I keep pushing them to go to the gemba and get the facts. Even though this is one of the most time consuming, and often frustrating, stages of the lean workout, most team members find it to be the most valuable. The teams that learn how to do it best are the most successful problem solvers and often produce the best outcomes in the completion of their Lean Workouts. Most importantly, they develop a critical skill set that they can use to solve future problems.

Mark S. Doman is a Pawley Professor in Lean Studies at Oakland University in the Human Resource Development Department and the Director of the Pawley Lean Institute. Prior to joining Oakland University, he had 25 years of business experience with Ford and AT&T, where he held various executive positions in operations, human resources and legal. He has led several major organizational change initiatives throughout his career that included corporate restructuring, Lean Workouts, kaizens, TQM and process re-engineering. He is the author of “A New Lean Paradigm in Higher Education: A Case Study.” Quality Assurance in Education, Vol. 19 No. 3, 2011 and “How Lean Ready Are You?” Target, Vol. 28 No. 2, 2012. His email address is doman@oakland.edu.